* is a registered trademark of European Bioplastics e.V. in the EU.

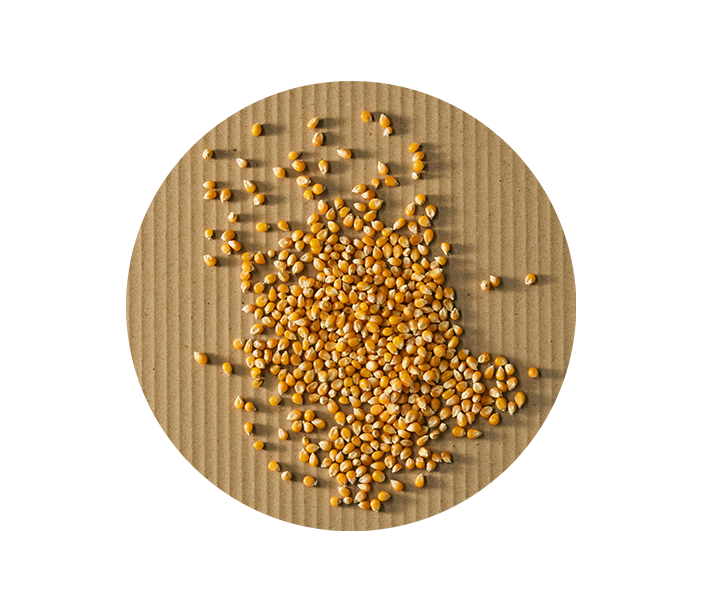

The raw material used for Corn Pack

originally comes from the corn plant.

When processing corn - for example

to cereals – a residual material is produced that is not

suitable for further use in

food production:

Cornmeal.

We use this residual material: The cornmeal is

puffed by means of a proven process

and changes its structure in the process.

After addition of an organic binder,

the material can be manufactured

into customised moulded parts.

Now Corn Pack is versatile: as

transport packaging for electrical appliances or

furniture, as inlays for product packaging, and as

shipping or delivery packaging for

temperature-sensitive goods such as food, pharmaceutical products or pet food.

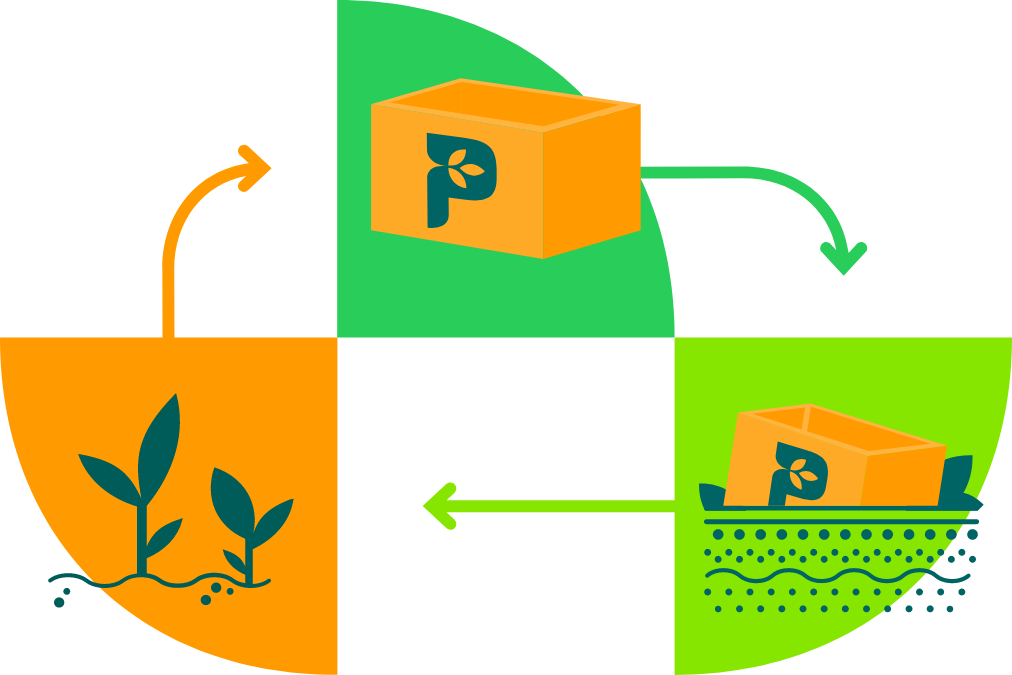

After use, Corn Pack decomposes in

the compost in a short time. Only the

CO₂ given off by the corn plant during

its growth has been stored. An

alternative is equally environmentally friendly

disposal via the organic waste bin.

From yoghurt pots to transport protection: most of the world’s existing plastic is used for packaging. With 90% of plastic waste not being recycled and recycling rates stagnating for years, plastic avoidance is the top priority.

If you want to avoid plastic, you need alternatives. And those that are not in their own way even more harmful to the environment. And this is where Plantera GmbH comes in with its Corn Pack innovation: as a sustainable, truly environmentally friendly alternative to conventional plastic packaging, especially expanded polystyrene.

With Corn Pack, we are setting a new standard for packaging: Corn Pack is an innovative, sustainable packaging material that is made from food industry waste and is biodegradable within a short time. Thus, after use, it can be easily disposed of in the organic waste bin or garden compost. The main ingredient of Corn Pack is cornmeal, a residual material produced during corn processing that is not suitable for further use in food production. The packaging material has similar properties to, for example, expanded polystyrene – also known as Styrofoam or Airpop. It is shockproof, shatterproof, insulating, food safe and can be custom made to measure. It thus offers a wide range of applications as product packaging, transport packaging for electrical appliances or furniture, and protection for temperature-sensitive goods such as food, pet food and pharmaceutical products.

Corn Pack is a brand of Plantera GmbH. We at Plantera think that the time is ripe for a new era. An era of packaging made from plants. It is our mission to leave nothing to future generations – except a future worth living. Our first step along the way is Corn Pack, a true innovation in the packaging market. Further steps will follow.

With its properties, Corn Pack offers for the first time a sustainable and genuine alternative to conventional expanded polystyrene. By significantly reducingCO2 emissions inproduction, use and disposal, Corn Pack not only protects goods during transport, but also the environment. The material is completely compostable without residue – even via garden compost. In the end, nothing remains but valuable nutrients – on which corn can grow again for the next generation of Corn Pack packaging.

Moreover, during composting, the material only releases the amount ofCO2 that the corn plant had stored during growth.

Corn Pack is mainly produced from the vegetable residue cornmeal, which is left over from corn processing. Cornmeal is not suitable for further use in food production. The cornmeal is “puffed”using a tried-and-tested process used in cereal production: cornmeal is preheated and put under pressure. An abrupt drop in pressure causes the grains to expand and acquire a foamy structure – similar to that when making popcorn. With the addition of an organic binder, solid moulded parts can be made from the material in the next step. For production, we use 100% green electricity to make the manufacturing process as sustainable as possible.

Together with the Georg August University of Göttingen, we developed the production process for Corn Pack 2022. This is based on extensive and patented research work. The University has licensed the rights to use the patent in the scope of packaging to Corn Pack.

With Corn Pack, we want to offer packaging that not only protects goods in transit, but also our environment. In this way, we are creating a genuine sustainable alternative to conventional, petroleum-based packaging materials such as expanded polystyrene, better known as Styrofoam.

It is shockproof, shatterproof, insulating, food safe and can be custom made to measure. As transport packaging, it protects furniture or household appliances, for example. As an inlay, it ensures that electrical appliances such as coffee machines sit firmly and securely in the product packaging. It also helps keep food, pet food or pharmaceutical products at the desired temperature during shipping, preserving quality and product safety.

Insulation performance is similar to that of polystyrene: 0.040 W/mK.

However, Corn Pack is not a petroleum-based material, but is made from 100% food manufacturing residues. This makes it a high-performance and at the same time sustainable alternative for insulating packaging – for the safe transport and shipping of food, pet food or pharmaceutical products, for example.

Corn Pack consists of puffed cornmeal, which due to its nature and structure is comparable to Styrofoam, but has a higher initial weight. The weight depends greatly on the intended use and the desired or necessary density of the material. The lightest Corn Pack packages start at a density of about 125 g/L.

Yes, Corn Pack is food safe.

Corn Pack is made from cornmeal, a rapidly renewable raw material that is a residual material in the food industry and therefore does not cause competition for land in cultivation. The residual material is also not suitable for further food production.

Even during production, considerably fewer resources are consumed than with petroleum-based products such as Styropor: 90% less energy is required for pressing the material alone compared with the classic manufacturing process for Styropor.

The material can be composted completely and without residue, releasing only as muchCO2 as the contained plant components have stored during growth. Thus, at the end of its product life cycle, nothing remains except valuable nutrients that are returned to nature.

Corn Pack consists of 100% residual materials from food production and, unlike many conventional packaging materials such as Styrofoam, is not made from petroleum as a raw material. Instead, the material is obtained from a residual material produced during corn processing: cornmeal. The starting material, which is not suitable for further use in food production, therefore does not have to be pre-produced, but is available in large quantities.

Over the entire life cycle, Corn Pack causes significantly less CO2emissions than classic plastic or Styrofoam packaging. The pressing process alone requires 90% less energy than the classic Styropor manufacturing process. After use, Corn Pack can be disposed of in the home organic waste bin or garden compost. In the process, the material only releases the amount ofCO2 back into the atmosphere that the corn plant had originally stored during its growth.

Since Corn Pack is 100% biodegradable, the material can be easily disposed of after use – both via the domestic organic waste bin and on the garden compost. In the process, it only releases the amount ofCO2 back into the atmosphere that the corn plant had originally stored during its growth.

No. Corn Pack is made from the purely vegetable residual material cornmeal, which is produced in large quantities during corn processing. Since our cornmeal is not suitable for further use in food production and the plants do not have to be specially cultivated for this purpose, the raw material used for Corn Pack is not in land competition with food production. The edible part of the corn plant is first processed into food and only the non-edible residue is then used for the production of our Corn Pack packaging.

Not least due to the increase in online shopping, more and more packaging material is being produced, which consumes valuable resources and contributes to the fact that more and more plastic is littering our planet.

This is where we come in: Corn Pack protects goods while enabling a better environmental footprint. This is because it is made from renewable raw materials, its product properties make it a real alternative to Styrofoam, and it is also 100% compostable.

Corn Pack also offers economic advantages: In addition to the pure purchasing costs, the disposal costs and the costs for licensing the packaging must also be taken into account. Since Corn Pack is made exclusively of natural, compostable materials, it incurs only about 1/10 the cost in licensing compared to traditional plastics such as Styrofoam.

Corn Pack protects goods to the same extent as comparable petroleum-based materials – and the environment at the same time. Styrofoam packaging, for example for transporting large electrical appliances, is produced at high energy cost, often used only once and then ends up in the trash. More than 60% of packaging is subsequently incinerated in Germany. If we consider only the waste generated in private households, the figure is even more than 94%. This releases a quantity ofCO2 that was previously bound in crude oil for thousands of years.

Corn Pack, on the other hand, is sustainable all the way from raw material to disposal, setting a new benchmark for a plastic-free packaging industry. The material developed in Germany consists mainly of a vegetable residue that is produced during corn processing and is available in large quantities: cornmeal. Moreover, the cornmeal used for Corn Pack is not suitable for further use in food production.

In a direct comparison, Corn Pack causes significantly lowerCO2 emissions over its entire life cycle. In the pressing process alone, 90% less energy is required compared to the classic manufacturing process for Styropor. After use, the material can be disposed of in the organic waste bin or composted at home, releasing only the amount ofCO2 back into the atmosphere that the corn plant originally stored during growth. At the end of its product life cycle, therefore, nothing remains except valuable nutrients that are returned to nature.

Corn Pack is robust and protects particularly well as a packaging material – also thanks to its high impact resistance, which corrugated board can only provide to the same extent with a high degree of processing and at correspondingly high costs. In addition, we can make custom mouldings from Corn Pack that perfectly enclose your goods for additional protection, including protection from moisture. The insulating effect also goes well beyond that of corrugated board, making Corn Pack ideal for transporting or shipping temperature-sensitive goods such as food, pharmaceutical products or pet food.